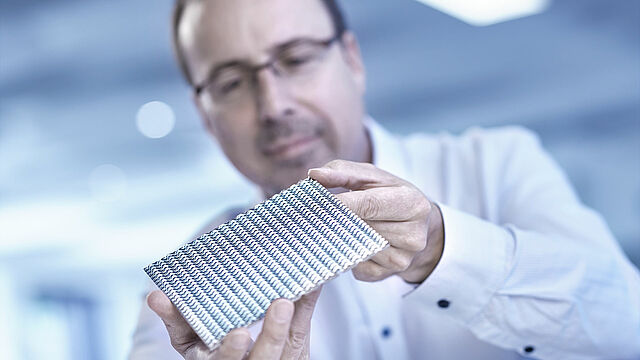

Processing, separation, conveying: in contrast to the usual round perforation, our CONIDUR® perforated plate has a special, triangular to semi-elliptical perforation, with an inclined, conical opening in the direction of passage.

The top and bottom are distinct from each other. This reduces passage resistance, prevents blockages and increases the throughput. The special manufacturing process enables the finest perforations in initial plate thicknesses, which can be many times the hole size.

Thanks to work hardening and subsequent treatment of the surface, CONIDUR® perforated plates have very good wear resistance. The special design offers numerous process technology advantages in various applications.